K-800

DIGITAL CUTTING STATION WITH WATERJET TECHNOLOGY

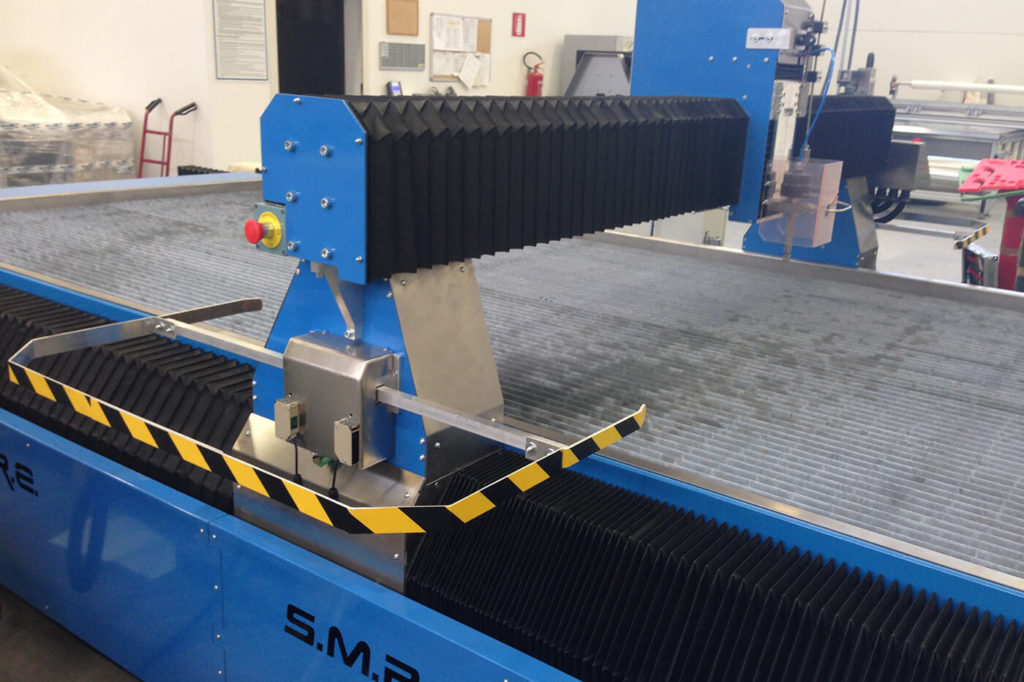

Whether you create mats and carpets, conveyor belts, advertisement gadgets, insulating foams, leather and faux leather products, plastic parts, rubber parts, non-woven products, components in PVC or industrial textiles, K-800 enables you to quickly prepare a cutting job and create 2D patterns and 3D objects with high speed and unparalleled precision.

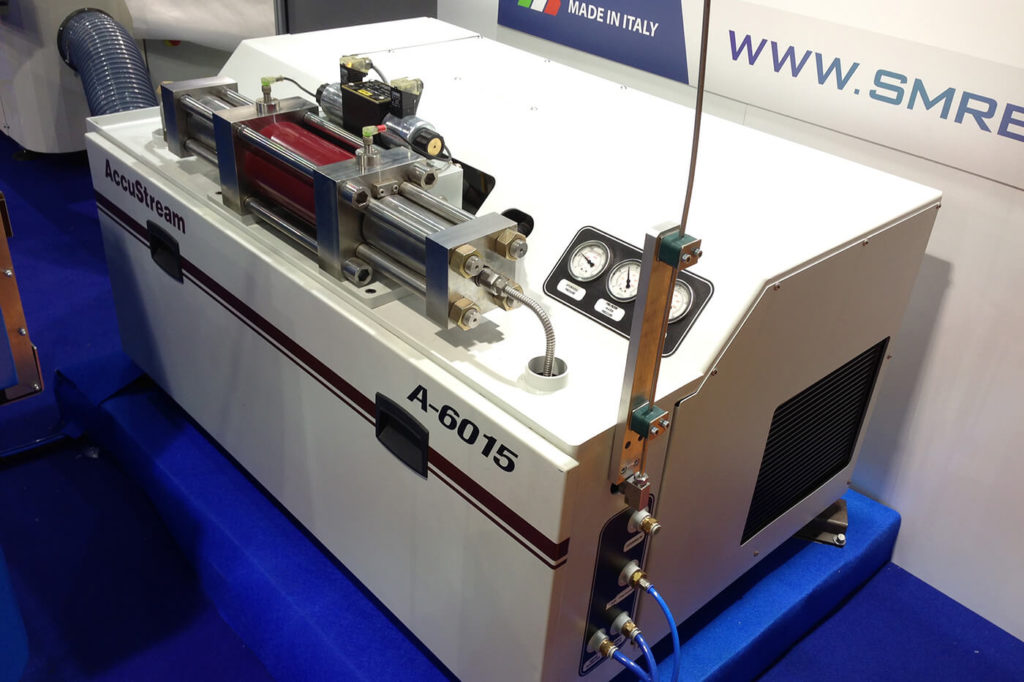

K-800 installs a waterjet cutting tool designed for heavy duty industrial cutting jobs. A series of high performance accessories – such as a laser pointer to determine the dynamic zero point, a vacuum turbine to extract water particles, a scanning and projection system for complex patterns – complete this machine and make it into the perfect solution for high precision cutting of complex and even highly complex patterns in soft and semi-rigid materials.

With a hyper pressure up to 4300 Bar, K-800 is very powerful, fast, highly efficient but easy-to-use cutting system suitable for a wide range of industries, both for large serial productions and for small production runs.

Technical specifications

Available usable dimensions | |

Width x length (m) | 2,5 x 1,5 |

Width x length (m) | 2,0 x 4,0 |

Footprint | Machine 2,0 x 4,0 m | Intensifier Pump (30 HP) |

X (mm) | 5253 | 1778 |

Y (mm) | 3260 | 864 |

H (mm) | 827 | – |

H MAX (mm) | 1726 | 1168 |

Weight (KG) | 3500 | 1500 |

Power (kW) | 4 | 22 |

Voltage (V) | 380 (3 phases + N + E) | 380 (3 phases + N + E) |

Circuit breaker (mA) | 300 | 300 |

Air (Quality Class 1.4.2.; ISO 8573) (bar) | 6 | 6 |

Air consumption (nl/min) | 250 (including pump) | – |

Max. axes speed X/Y/Z/W (m/min) | 30/30/15/15 | – |

Precision axes repeatibility (mm) | 0,1 | – |

Min. water quantity (l/min) | Cutting: | 5 |

Cooling: | 8 | |

Min – Max. water pressure (bar) | Cutting: | 1,5 – 7,2 |

Cooling: | 2,5 – 7,2 | |

Certification | 2006/42/EC; 2014/30/EU; EN ISO 12100 | |