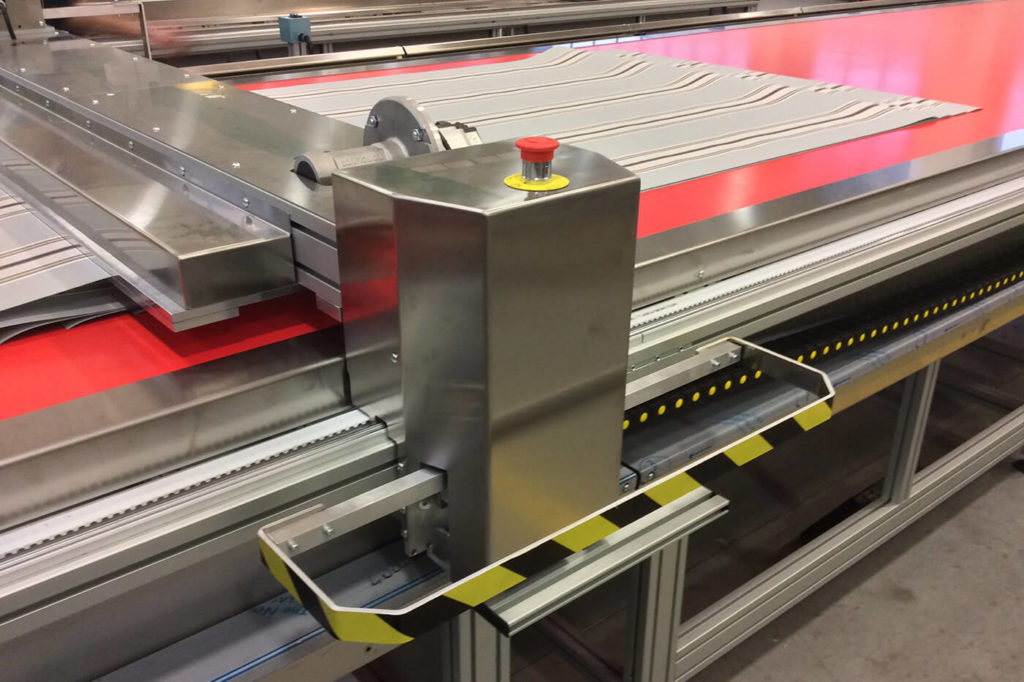

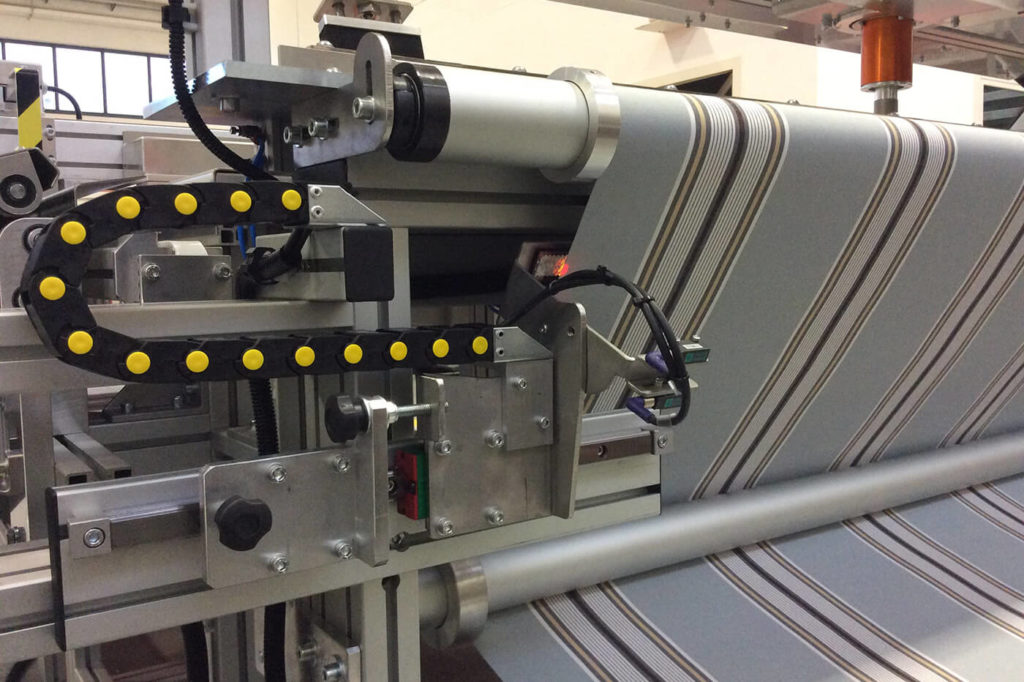

Originally designed to cut specialty fabrics typically used in the awning and sun protection industry, it’s solid industrial structure, brushless motors, and quality cutting tools make this machine an ideal solution for manufacturers in many other industries as well.

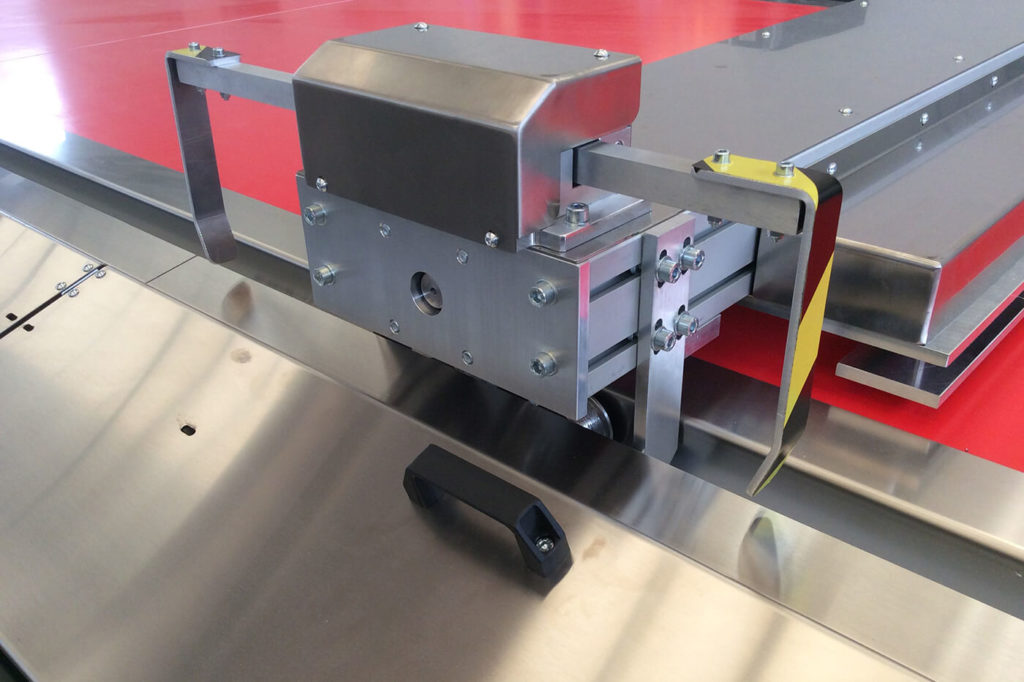

SM-400-TA installs a wide range of industrial cutting tools for the creation of top quality fabric panels. A selection of accessories make this machine the complete solution for your panel cutting requirements.

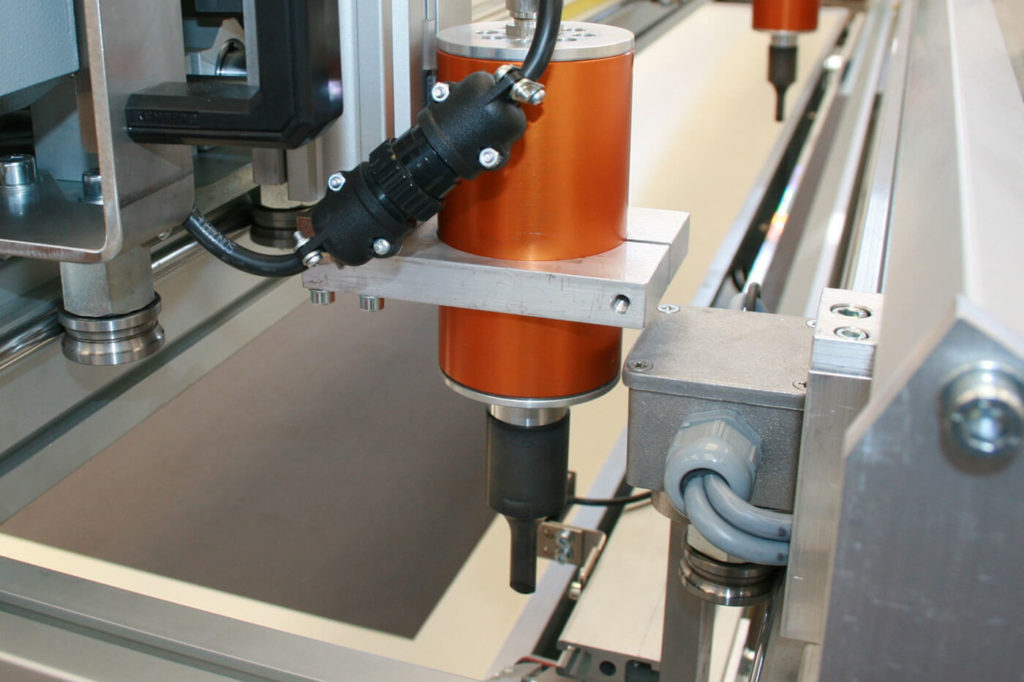

To solve the problem of shrinking crystal (clear) PVC we developed a system for the just-in-time heat treatment with infrared light. After the treatment the crystal PVC will remain perfectly stable and can be integrated in products such as industrial doors, tents or terace covers without the danger of shrinkage, even when exposed to sunlight or cold.

First introduced in 1999, many innovative solutions were integrated into this machine to ensure absolute reliability and cuts of the highest quality. If you’re looking for fast and efficient production cycles and high quality cut panels made with an easy-to-use machine, SM-400-TA is the solution for you.

EASY AWNING MAKER

This highly specific production software makes the creation of awning panels extremely simple. A series of preset awning patterns to choose from ensure significant time saving when programming production cycles. Desired overlaps and lateral hems are calculated automatically, taking into account the width of the roll and the desired width of the final product. The user interface is an easy-to-use touch screen. All the operator has to do is insert the parameters. SM-400-TA can be connected with an optional bar code reading software to further reduce the need for human intervention. The bar code reader will automatically pick the order at hand from the company order data base and set the vital parameters for the upcoming production cycle. The operator pushes the START button and the machine will automatically do its job, creating as many panels as needed.